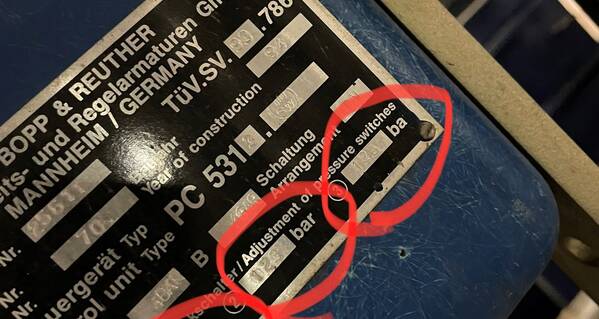

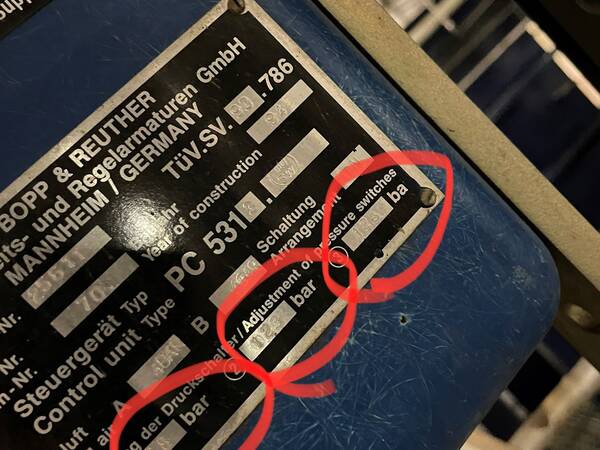

Safety and reliability are not optional in industrial processes where pressure protection plays a critical role. In sectors such as energy, oil & gas, ethylene production and waste incineration, operators have relied for decades on pneumatically assisted spring-loaded safety valves. In this field, one name has become almost synonymous with reliability: the PC53 Pneumatic Control Unit by Bopp & Reuther. And rightly so. Since its introduction in 1986, the PC53 has proven itself as a robust and reliable control unit for applications involving steam, gas and liquids. In many installations, it is still operating flawlessly today — in some cases for almost forty years. But that is precisely the pitfall.

Spare parts are becoming increasingly scarce

The PC53 has been out of production since 2017. While it is still technically serviceable, spare parts are becoming harder and harder to obtain. This is not a theoretical concern, but a real risk to the continuity of industrial installations.

I fully understand why many operators do not yet feel an urgent need to replace their PC53 units:

- The PC53 is extremely robust

- Our service department knows these units inside out

- Repairs and maintenance are often still carried out without issues

The result? A sense of security.

But let’s be honest: a unit designed in 1986 may feel familiar, yet it is by definition not future-proof.

The question is not if this will become a problem, but when.

Where are PC53 units most commonly found?

We still encounter PC53 units frequently in:

- Power plants (steam applications)

- Ethylene production facilities

- Waste-to-Energy plants (biomass and municipal waste)

- Paper mills

- The oil and gas industry

These are precisely the environments where unplanned downtime or compromised pressure protection is simply not an option.

The PC50: a proven successor, not an experiment

As early as 2000, IMI Bopp & Reuther introduced the PC50 as the successor to the PC53. The PC50 is based on the same operating principle, but has been adapted to meet the demands of modern industrial processes.

Easy transition

It is important to emphasise that the transition to the PC50 is technically straightforward. Dimensions and connections can be aligned with existing specifications, allowing integration into current installations without major modifications.

Why switching now makes sense

The PC50 offers tangible improvements that directly enhance safety and reliability:

- Smaller pressure tappings

Ø21.3 × 3.2 mm — less sensitive to vibration and therefore more stable in industrial environments. - Improved heating system

Specifically developed for Ex applications at low temperatures (-10°C to +5°C), with enhanced control and monitoring. - External insulation option

For extreme conditions (< -20°C), including advice on insulation and heat tracing of tapping lines.

In short: a future-oriented solution, designed to anticipate risks rather than react to them.

Service remains, risks are reduced

At Hitma, we continue to do what we do best: support, maintain and advise. Our certified service engineers provide maintenance for both the PC53 and the PC50. But let’s be realistic: service alone cannot solve the issue of diminishing spare parts availability.

That is why my message is clear:

Do not wait until replacement is forced by a failure or lack of parts.

Take control of the safety and continuity of your installation now.

By switching to the PC50 in good time — optionally supported by a Hitma service contract with preventive maintenance — you avoid unpleasant surprises and remain in control.

Would you like to discuss your specific situation or understand what the transition would mean for your installation? I would be happy to think along with you.

Also read: Pneumatic safety valves: why choose the PC50 as successor to the PC53?